PPR Fittings

connection technique using heated-tool socket welding

When the pipe and the fitting are welded, their plastic materials fuse together to from a homogeneous, firmly bonded whole. Special tools are used to heat up pipe and fitting, which are then just joined together. This connection is lastingly leak proof.

System components

Fittings

the PP-R-metal connection of the ROXY fitting excels by its leakproofness and resistance to torsion. This connection withstands decades of operational loads without any difficulty. Thanks to the specific geometry of their inserts, which are made of high-grade brass, the mouldedparts meet the highest safety standards and guarantee safe laying.

The metal threads of the ROXY brass components meet the requirements of the din EN 10226 standard and are manufactured from high-quality brass. Moreover, the material complies with the current version of the recommendations (as at 2014) of the federal Environment Agency on “Materials suitable from a drinking water hygiene point of view”.

This guarantees that the limit values of the “Deutsche Trinkwasser-verordnung (TrinkwV 2001)” (German Drinking Water Ordinance)are reliably observed. All ROXY fittings are compatible with all ROXY pipes.

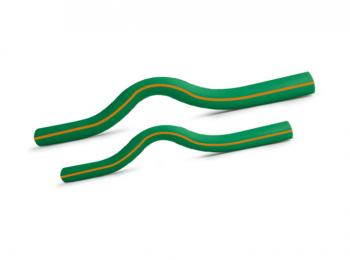

Pipes and Fittings

All pipes and fittings of the ROXY installation system are made of PP-R, with only high-quality raw materials being used. This raw material is equipped with high-grade stabilizers. The stabilizer package protects the polymer from oxidation, which may occur, for example, following long-term exposure to high temperatures > 70 C and high pressure.