ASTM System

Features of Roxy U-PVC Systems Lead free product

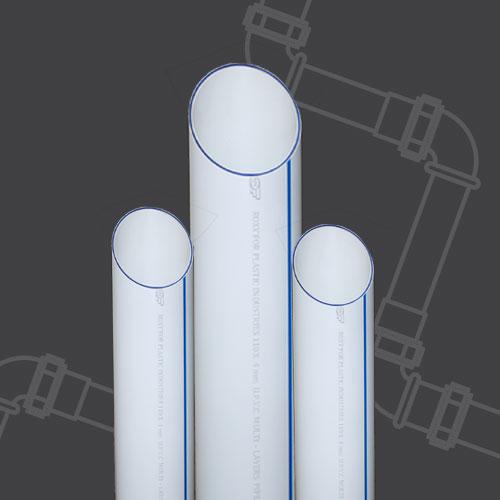

UPVC (pipes & fittings) are produced and manufactured from raw materials completely free from heavy metals. This pipe is %100 safe for use in various applications related to drinking water. It is also environmental friendly and at the same time preserves its physical and material properties.Meets health specifications.

Meets the followed standard physical and mechanical proprieties, in addition to its characteristic of stability and thermal balance. The latest technological innovations are used in the manufacturing process of Roxy Plast U-PVC (pipes & fittings), from the manufacturing stage till the product reaches the end user, in order to ensure the highest levels of quality assurance and reduce any defects or errors in the production and process.

Non-toxic

Roxy Plast U-PVC (pipes & fittings) are produced and manufactured from non-toxic materials, which ensures that this category of pipes can used be in drinking water pipes without any risk. In addition, Roxy Plast U-PVC (pipes & fittings) do not change the taste, smell of water, or other liquids, nor do they allow the growth and accumulation of bacteria or parasites.

Flexibility

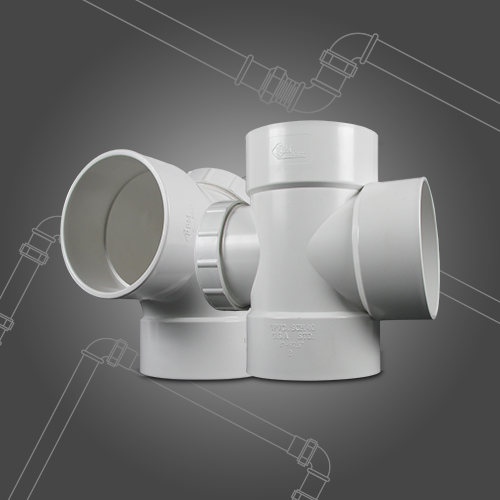

Roxy Plast U-PVC (pipes & fittings) systems can be categorized as "flexible system in design", and this feature of "flexibility" offers a tremendous advantage for this type of system compared with other types of systems that may not be flexible enough to make the installation process easy.

For flexible pipes in terms of design: - The soil supports the pressures and loads on the pipe (including the weight of the soil), and as a result a slight distortion of the pipe, but it is not broken. For pipes made of conventional materials, the soil directly concentrates the loads and pressures on the pipe head which can result in huge damage to the pipe body. There are no deformities of this type of pipe, but it collapses, resulting in fractures. For most good soil types (for example, granular soil), the soil supports all loads and pressures. Due to the ease of doing work in this category of soil, the distortion ratio of Roxy Plast U-PVC (pipes & fittings) ranges from 1 to only %2, which does not affect the functional properties or the intensity of the coherence and cohesion of the network at all. For all pipe materials, the very difficult soil conditions may require extensive examination and inspection or calculations by qualified civil engineers to do so. Some European and national requirements also require certain calculations for piping systems.

Fire resistance

Roxy Plast U-PVC (pipes & fittings) are mainly characterized by flame-retardant properties because they contain chloride, even in the absence of fire retardants. For example, the ignition temperature of PVC is 455 ° C, an extremely high temperature, and it is less likely to be exposed to fire hazards because of the difficulty of igniting it. In addition, the heat emitted by combustion is significantly less in the case of PVC when compared to materials such as polyethylene and polypropylene. Therefore, U-PVC pipes have high fire resistance.

Chemical resistance

Due to the nature of the polymer chain formation, which is formed through the individual bonds of the carbon atoms, U-PVC is characterized by its tremendous chemical resistance to other plastics used for general purposes, for example, polyethylene, polypropylene or polystyrene.

Long life time and High Resistance

The capacity of Roxy Plast U-PVC (pipe & fittings) is similar to that of all other thermoplastic materials with the degree of chemical degradation of polymers used in the manufacture and production of these pipes. However, unlike all other thermoplastic pipes, U-PVC pipes are non-oxidant. The stabilizers are used in U-PVC pipes to prevent polymer degradation during the evaporation process and the storage of pipes before burying them in the ground. However, when burying underground pipes, no chemical degradation is expected. For this reason, it is expected that the potential of U-PVC material in buried pipes will be very good (perhaps more than 1,000 years). In the standard of drinking water and drainage pipe lines Roxy Plast U-PVC (pipe & fittings) meets the expected shelf life of U-PVC pipes under pressure that can be stabilized in the light of pressure tests up to (20,000) hours, which would allow the possibility of estimating probability through extrapolation and predicting age under

pressure Between 50 and 100 years. The practical experience in Germany has shown thatU-PVC pipes buried underground that have been tested after 60 years of active use are still in good condition for the purposes for which they were designed. Therefore these tubes have the ability to work and endure for a period of another 50 years.

Stability and mechanical stability

Roxy Plast U-PVC (pipe & fittings) are made of chemically stable materials that have minor changes in the structure of the molecule and are subject to very minor changes in their mechanical resistance. However, long chain polymers are rubber viscous materials, which may be deformed by external application of external forces, even if the external force is less than the point of submission. This is called change in shape. Although U-PVC pipes are made of rubber sticky materials, the change in shape may be very slight compared to other types of plastic pipes because of the limited movement of the molecule at normal temperature, as opposed to polyethylene, polypropylene , Characterized by the massive movement of their molecules in the non-shaped sectors.

Impact Resistance

Roxy Plast U-PVC (pipe & fittings) are highly resistant to collisions from their cast iron pipe or ceramic pipes, which are subject to a lot of loss due to fracture and improper handling of these pipes during transportation, storage and installation.